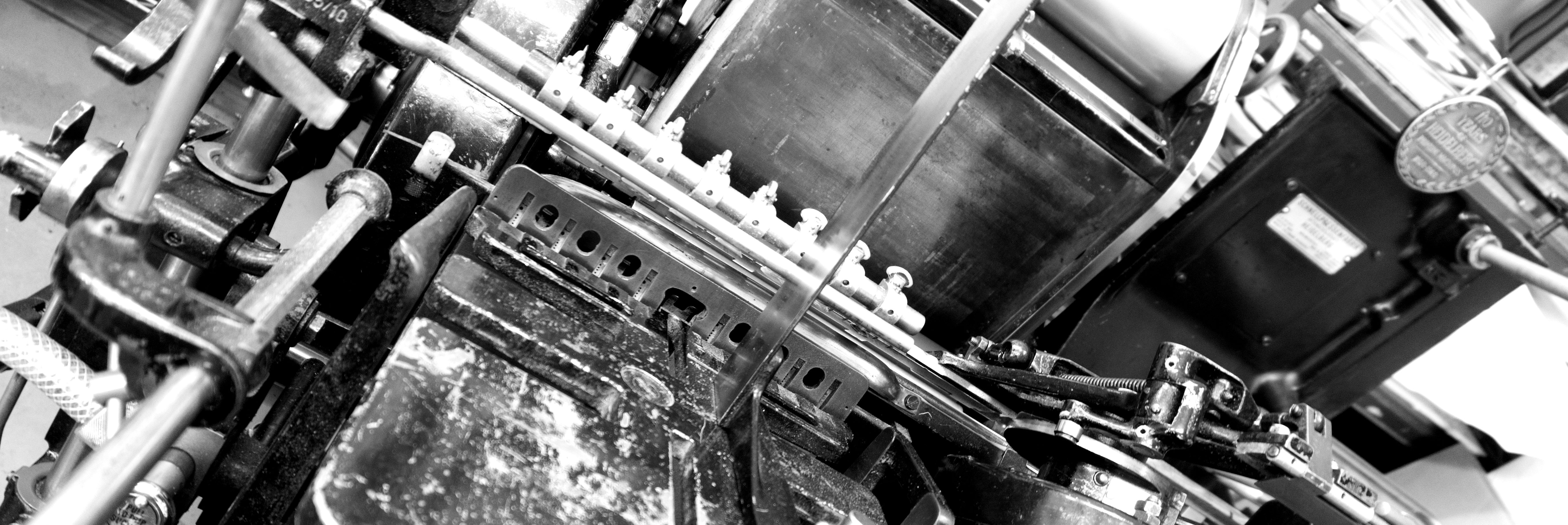

The press consists of two belts, one containing a set of plates for the recto pages, the other belt containing a set of plates for the verso pages. A belt press is used for the high-speed production of books. These presses are also often used inline with other types of presses, such as flexo and lithographic, or with finishing equipment such as embossers and die-cutters. Narrow web rotary presses utilizing photopolymer plates and ultraviolet curing ink are capable of high-speed multi-color letterpress printing, and can handle web widths of up to 24 inches. Rotary sheetfed presses are a casualty of the declining market for letterpress printing, but some web-fed rotary presses are still utilized. The curved plate is brought in contact with a rotating impression cylinder, the paper passing through the nip between the two cylinders. A rotary press utilizes a rotating plate cylinder to which a curved metal relief plate is mounted. In some configurations, the typeform is in a vertical position and both the flatbed and the cylinder move. In some configurations, the flatbed moves beneath the rotating cylinder, effecting ink transfer. On a flatbed press, the typeform is again placed on a flatbed, but the substrate is carried on a rotating impression cylinder. Small platen presses are used to print short-run jobs, such as invitations, announcements, stationery, etc. A platen closes over the inked typeform and substrate, exerting pressure and transferring the ink from the type to the paper. A platen press utilizes a flat plate or typeform mounted on the bottom-or flatbed-of the press. There are essentially four types of letterpress presses: (See Type.) Molded rubber photopolymer plates have for the most part replaced the older metal stereotypes and electrotypes, and are prepared in a manner not unlike plates produced for flexography. Two versions of these early letterpress plates are stereotypes and electrotypes, two different ways of creating a solid, curved metal plate from a locked-up typeform. Eventually, others developed means of casting type a line at a time or, even more efficiently, making a mold of an entire page of locked-up type and making a solid plate out of it, which could then be wrapped around a cylinder. These could all be fit into a frame, inked, and printed. He then poured molten lead into the mold and let it cool. He solved the problem by casting type, or forming a matrix with a punch that made a mold of a particular letter. Johann Gutenberg's important contribution to printing was not really the idea of the printing press, but an effective image carrier. There are several parts to a letterpress press: The use of photopolymer plates is reviving letterpress to an extent, however. Consequently, it takes a great deal of effort to ensure that that small highlight areas do not pierce the substrate and that the solids print with uniform density (in flexography, the resilience of the rubber plate eliminates this problem). For example, for a given amount of impression pressure, more pressure will be exerted on small highlight dots than on larger blocks of solids or shadows.

Letterpress plates exert varying amounts of pressure on the substrate during printing. The decline of letterpress is due primarily to the extensive and expensive makeready procedures required. The legacy of letterpress lives on in flexography, a type of relief printing utilizing flexible rubber plates. Although the first printing presses ever created were letterpress devices, the use of letterpress printing has been declining due to advances in other forms of printing, especially offset lithography and gravure. The type can be either individual characters or plates made with raised type. The oldest of the major printing processes distinguished by its use of raised metal type.

0 kommentar(er)

0 kommentar(er)